——Six models: ZSM60, ZSM80, ZSM90, ZSM100, ZSM125 and ZSM168

——Finished production fineness: 325-2500 mesh (47-5 microns)

——Capacity (ton/hour) ranges from 0.3T/H to 25T/H

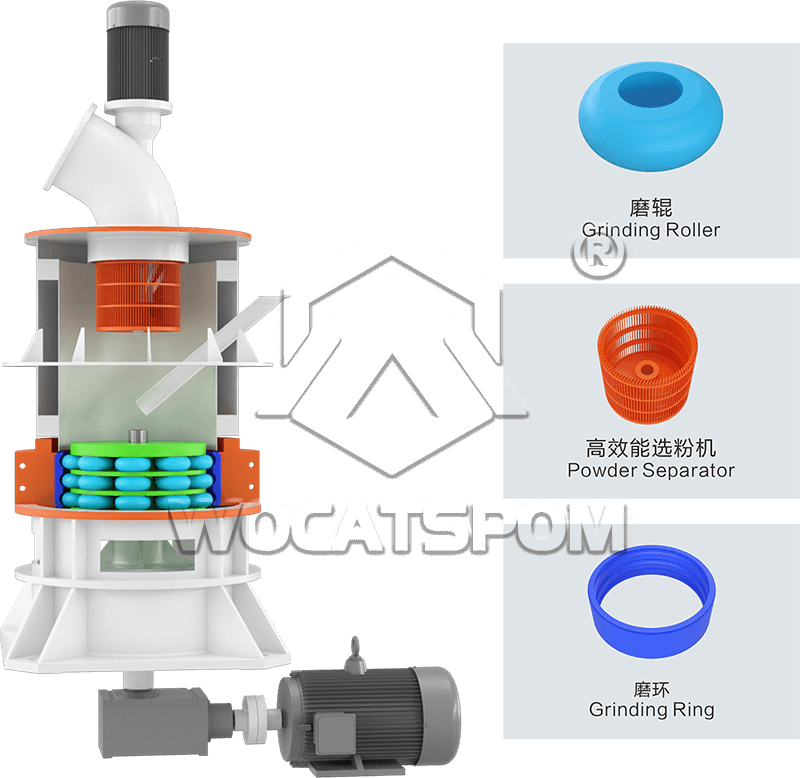

Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill,

ultra fine powder grinder) is designed to produce ultrafine powder 325 mesh to 2500 mesh. The hardness of the material determines the life of the wearing parts. It has strong technical and cost

The ultrafine mill is suitable for processing the low and intermediate hardness brittle materials which are non-flammable and non-explosive,such as dolomite, calcium carbonate, kaolin, bentonite, talc, mica, attapulgite, barite, gypsum and graphite and so on. It has been widely applied in paint, paper making, pigment, rubber, plastic, padding, cosmetic, chemical supplies and many other industrial fields.

1. The yield is 40% higher than other mills.

2. High utilization rate of Wear material:2-5years.

3. Adjustable particle size:325-3000mesh.

4. High safety and reliability. The design of the mill is rigorous, so no screw loosening to damage the machine.

5. Closed system, so it is the green and ideal equipment for environment protection.

| Model | ZSM60 | ZSM80 | ZSM90 | ZSM100 | ZSM125 | ZSM168 | |

| Ring rollers(pcs) | 12 | 21 | 24 | 36 | 44 | 44 | |

| Working diameter(mm) | φ600 | φ800 | φ900 | φ1000 | φ1250 | φ1680 | |

| Number of grinding rings and raceways(pcs) | 1x3 | 1x3 | 2x4 | 2x4 | 2x4 | 2x4 | |

| Host speed(r/min) | 230-240 | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 | |

| Maximum feed size(mm) | ≤10 | ≤10 | ≤20 | ≤20 | ≤20 | ≤20 | |

| Finished particle size(mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 | 325-2500 | |

| Capacity (kg/h) | 300-3000 | 500-4500 | 800-6500 | 1000-8500 | 2500-14000 | 5000-25000 | |

| Feeding machine | Type | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder | Skirt belt feeder |

| Type | B300x60 | B300x60 | B300x60 | B300x60 | B300x80 | B400x80 | |

| Power(kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Host | Power(kW) | 45 | 55 | 45x2 | 132 | 185 | 315 |

| Powder separator | Power(kW) | 15 | 18.5 | 22 | 30 | 75 | 132 |

| Dust collector | Type | DMC96 | DMC160 | LDCM35-7 | LDCM35-8 | LDCM72-8 | LDCM72-8x2 |

| Power(kW) | 37 | 45 | 55 | 75 | 132 | 220 | |

| Discharge screw | Power(kW) | - | 3 | 3/5.5 | 7.5 | 7.5 | 7.5x2 |

| Discharge valve | Power(kW) | 0.75x2/0.75x1 | 0.75x1 | 1.1x1 | 1.5x1 | 1.5x2 | 1.5x2 |

| Air compressor | Power(kW) | 7.5 | 11 15 | 15 | 22 | 37 | 55 |

| Gross weight(t) | 12.5 | 16.5 | 24.6 | 32.2 | 54 | 76 | |

| Dimensions(mm) | 12000x4500x6000 | 14000x4700x6200 | 14700x4800x8600 | 18000x4600x8600 | 14000x9000x10250 | 26300x7500x11900 | |

If the parameters are not displayed completely, please slide the table to the left.

Chat Online

Chat Online Get Solution

Get Solution