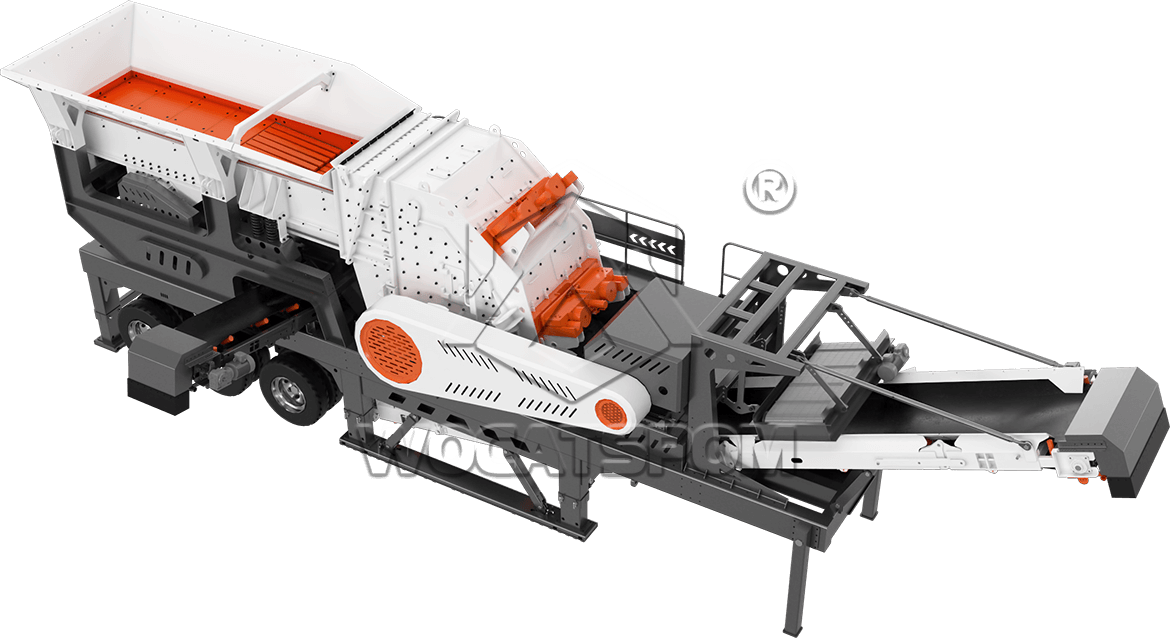

WOCATSPOM LF series Wheel-mounted Impact Crusher is a mobile crushing station designed by WOCATSPOM Group for primary crushing. It is mainly used to process ores with a compressive strength not exceeding 350 MPa, and limestone, slag, coke, coal, etc. It has the characteristics of large crushing ratio, good product particle shape and uniform particle size. Mainly used in water and electricity, highways, building materials waste treatment and artificial construction aggregate processing industries.

WOCATSPOM LF series wheel-mounted Impact Crusher is mainly composed of a vibrating feeder, a LF large-diameter impact crusher, a portable chassis and a set of electrical control system. It is one of the important equipment in the primary crushing stage. It has the characteristics of stable performance of portable mobile equipment, easy movement, quick installation, easy maintenance, and integrated electrical control. Its equipped grate feeder can pre-screen out waste soil and small-sized aggregates in the raw materials, improving for primary crushing efficiency and aggregate cleanliness, it uses the LF series large-diameter impact crusher with a large feed opening, large crushing ratio and excellent product particle shape. It is the first choice for processing large-sized soft rocks and construction waste.

1. Pre-screening function facilitates waste removal. The WOCATSPOM LF series wheel-mounted impact crusher is equipped with a feeder with grizzly, a dual-channel discharge hopper and a side discharge belt conveyor, which can pre-screen out the waste soil in the raw materials.

2. The feeder has a large capacity and the feeding speed is adjustable. The standard volume of the feeder is 6.5m³, and can be widened to 8m³. The feeding storage capacity is large, it can feed materials evenly and continuously, and the feeding speed can be adjusted to meet different working conditions.

3. Efficient and stable main machine. The main machine is equipped with LF series large-diameter impact crusher, which is efficient and stable.

4. Equipped with boots, the working mode and mobile mode can be easily switched. After the production site is leveled and the machine position is determined, the hydraulic system controls the landing of the boots to quickly enter the operating mode without manual operation.

5. The vehicle-mounted belt conveyor, convenient to install. It has a vehicle-mounted discharge belt conveyor and can be used with other equipment, The on-board belt conveyor minimize on-site installation work and facilitate changing production sites.

6. Flexible delivery methods. The machine can be transported as a whole or disassembled and transported in containers.

7. No need for cement foundation, reducing costs. The working site only needs to have the road surface leveled and compacted to achieve working conditions. There is no need for cement foundation leveling and hardening, which reduces foundation construction costs.

8. Modular design, providing multiple options. The chassis and tire set adopt a modular design, which can quickly switch between frame type and wheel-mounted type to meet clients' multiple choices.

Model | K3-LF150-2C | K3-LF250-2C | K3-LF350-2C |

Vibrating feeder | GZD9638 | GZD1142 | GZD1349 |

Impact crusher | LF150 | LF250 | LF350 |

Maximum feeding size | 500mm | 700mm | 800mm |

Capacity | 80-150tph | 100-200tph | 200-400tph |

Power of the impact crusher | 160kW | 250kW | 315kW |

Operation weight | 32t | 49t | 51t |

Operation Dimensions(L*W*H) | 11900*4385*4098mm | 12691*4485*4298mm | 15350*6025*4500mm |

If the parameters are not displayed completely, please slide the table to the left.

Chat Online

Chat Online Get Solution

Get Solution