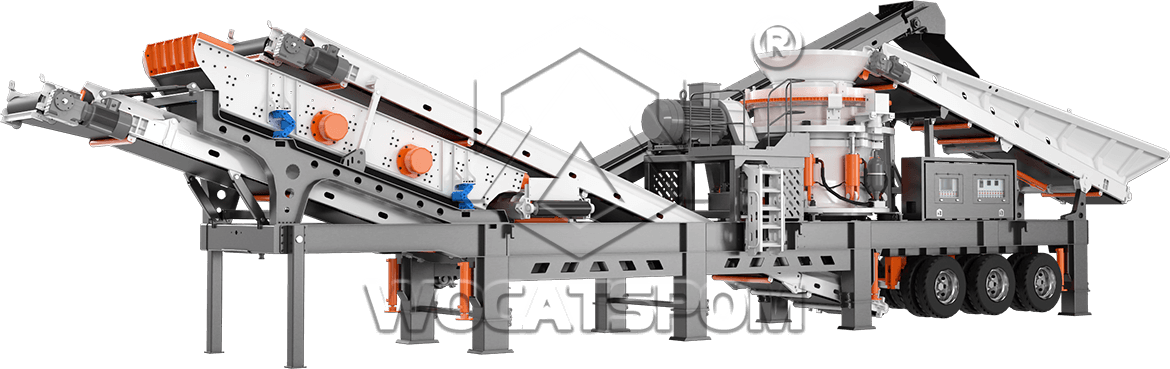

K3-RS-2C Mobile Cone Crushers including the high production efficiency cone crusher with a high efficiency vibrating screen, stones that do not meet the standards are then transported to the crusher through the return screen and return belt for re-crushing and screening,this design making the machine a self contained working system,the production capacity and performance of mobile equipment are comparable to fixed production lines.It can be used independently when only one kind product required, or it can provide more flexible process configurations based on customer requirements for material types and products in the process.

1.K3-RS-2C’s feeding belt has an adjustable speed and can feed materials evenly. It is equipped with a 4.5m³ transfer feeding silo and has the function of transferring and storing materials to ensure sustainable and uninterrupted operation and is more energy-saving.

2.The hopper can be loaded with a loader to ensure a variety of flexible feeding; it solves the problem of idle materials participating in the crushing process.

3.The main equipment adopts hydraulic cone crusher, which can be equipped with return screening equipment to become an independent crushing unit to meet various combinations of customers.

4.The working site only needs to have the road surface leveled and compacted to achieve working conditions. there is no need for cement foundations, after the station layout, the hydraulic cylinder legs are extended to quickly enter the working mode.which greatly reduces costs.

5.The belt conveyor are vehicle-mounted,minimize on-site installation work,also easier move to other project site.

6.The frame and tire module adopt a modular design, which can quickly switch between frame type and tire type; satisfying customers' multiple choices.

Model | K3-HP200RS-2C | K3-HP300RS-2C | K3-HP400RS-2C | K3-SH160RS-2C | K3-SH250RS-2C |

Cone crusher | HP200 | HP300 | HP400 | SH160 | SH250 |

Belt feeder | B800 | B1000 | B1200 | B800 | B1000 |

Return screen | YK1530 | YK1640 | YK1750 | YK1530 | YK1640 |

Capacity Potential(t/h) | 90-250 | 115-440 | 140-630 | 48-345 | 90-605 |

Max feeding size (mm) | 235 | 240 | 310 | 235 | 300 |

Weight(t) | 50 | 56 | 65 | 46 | 51 |

Transport dimensions(mm) | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship | Disassemble and ship |

Working dimensions(mm) | 21700*3888*5150 | 21700*3888*5950 | 21700×4500×5950 | 21700*3888*6250 | 21700*3888*6450 |

If the parameters are not displayed completely, please slide the table to the left.

Chat Online

Chat Online Get Solution

Get Solution