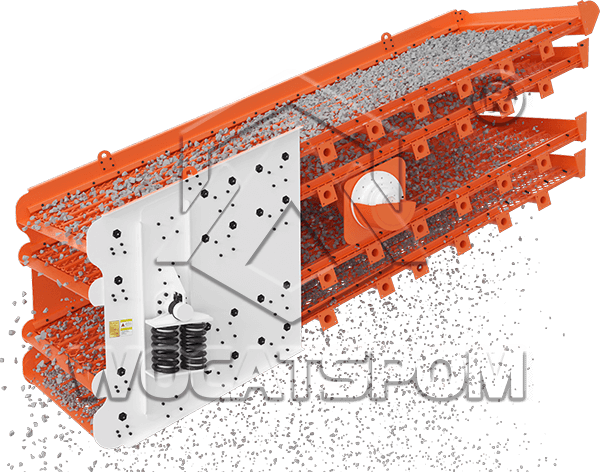

Screens are commonly utilized in mining operations and aggregates production to separate rocks, ores, and other materials by size, shape or other characteristics. The circular vibrating screen mainly consists of a screen box, screen mesh, vibrator, damping spring device, and chassis. Using a cylindrical eccentric shaft exciter and an eccentric block to adjust the amplitude. The vibrator is installed on the side plate of the screen box and is driven by a motor to generate centrifugal inertia force through the rotation of a triangular belt, forcing the screen box to vibrate. The side plate of the screen machine is made of high-quality steel plate, which is connected to the crossbeam and base of the exciter through high-strength bolts or ring groove rivets. The vibrator is installed on the side plate of the screen box and is driven by a motor to rotate through a coupling, generating centrifugal inertia force and forcing the screen to vibrate.

High production efficiency

Due to the strong vibration of the screen box, the phenomenon of material blockage in the screen mesh is reduced, resulting in high screening efficiency and productivity of the screen mesh.

Maintenance friendly

The modular design, wear and impact resistance linings serve to simplify and reduce the need for maintenance.

High performance

The motor is directly connected to the drive, reducing the energy consumption of the transmission system. Optional spray systems and sealed dust prevention systems are available, which helps with environmental protection.

| Model | Screen Surface Specification(mm) | Layer | Feeding Size(mm) | screen mesh Size | Processing Capacity(t/h) | Power(kw) | Vibrating Frequency(r/min) | Stroke(mm) |

| 2YZK1237 | 3700*1200 | 2 | ≤400 | 3-50 | 30-100 | 5.5 | 970 | 5-9 |

| 3YZK1237 | 3700*1200 | 3 | ≤400 | 3-50 | 30-100 | 7.5 | 970 | 5-9 |

| 2YZK1548 | 4800*1500 | 2 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 3YZK1548 | 4800*1500 | 3 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 2YZK1848 | 4800*1500 | 2 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 3YZK1848 | 4800*1800 | 3 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 4YZK1848 | 4800*1800 | 4 | ≤400 | 3-80 | 56-330 | 22 | 970 | 5-9 |

| 2YZK1860 | 6000*1800 | 2 | ≤400 | 3-100 | 65-586 | 18.5 | 970 | 5-9 |

| 3YZK1860 | 6000*1800 | 3 | ≤400 | 3-100 | 65-586 | 22 | 970 | 5-9 |

| 4YZK1860 | 6000*1800 | 4 | ≤400 | 3-100 | 65-586 | 30 | 980 | 5-9 |

| 2YZK2160 | 6000*2100 | 2 | ≤400 | 3-100 | 81-720 | 22 | 980 | 5-9 |

| 3YZK2160 | 6000*2100 | 3 | ≤400 | 3-100 | 81-720 | 30 | 970 | 5-9 |

| 4YZK2160 | 6000*2100 | 4 | ≤400 | 3-100 | 81-720 | 30 | 980 | 5-9 |

| 2YZK2460 | 6000*2400 | 2 | ≤400 | 3-150 | 100-810 | 22 | 970 | 5-9 |

| 3YZK2460 | 6000*2400 | 3 | ≤400 | 3-150 | 100-810 | 30 | 980 | 5-9 |

| 4YZK2460 | 6000*2400 | 4 | ≤400 | 3-150 | 150-850 | 37 | 980 | 5-9 |

| 2YZK2870 | 7000*2800 | 2 | ≤400 | 5-100 | 120-680 | 22*2 | 750 | 8 |

| 3YZK2870 | 7000*2800 | 3 | ≤400 | 5-100 | 180-720 | 22*2 | 750 | 8 |

| 2YZK3070 | 7000*3000 | 2 | ≤400 | 5-100 | 200-700 | 37 | 750 | 8 |

| 3YZK3070 | 7000*3000 | 3 | ≤400 | 5-100 | 230-800 | 45 | 750 | 8 |

If the parameters are not displayed completely, please slide the table to the left.

Chat Online

Chat Online Get Solution

Get Solution